Exterior Cladding

Ventilated Facades

WHAT ARE

Ventilated Facades

Porcelain slabs installed on a high performance system used to design the exterior of custom homes and commercial buildings.

what makes a facade system

Porcelain facades consist of two parts, large format porcelain slabs and the ventilated system.

Porcelain Slabs

Highly resistant to scratches and impacts. Withstands extreme temperatures without cracking, degrading or fading. Non-combustible, UV resistant and non-porous.

Ventilated System

Innovative facade installation system that offers the advantages of permeability, thermal insulation, solar protection, acoustic insulation and water impermeability.

how it works

The Major Advantages of Ventilated Facades

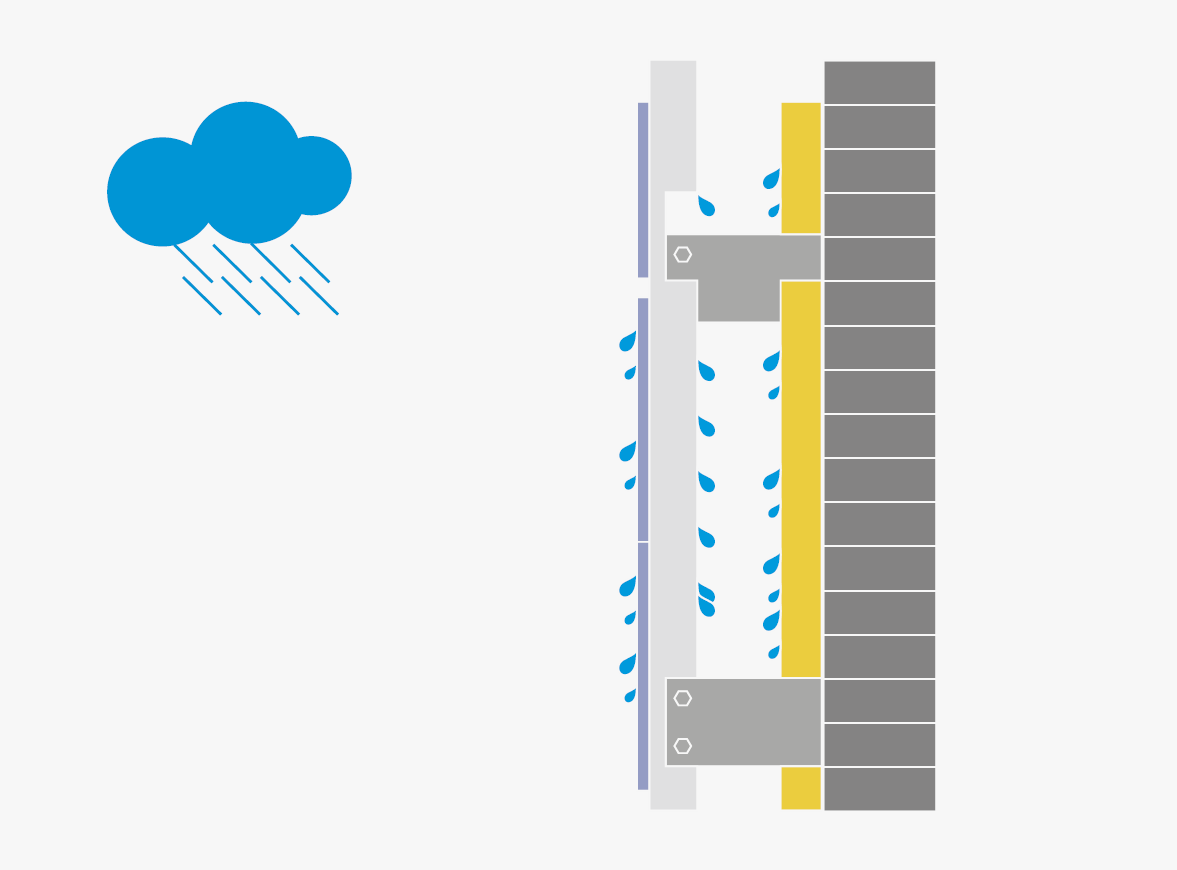

Permeability

Moving air diffuses water vapor from the inside out and facilitates facade “breathing” which prevents condensation from forming behind the panels.

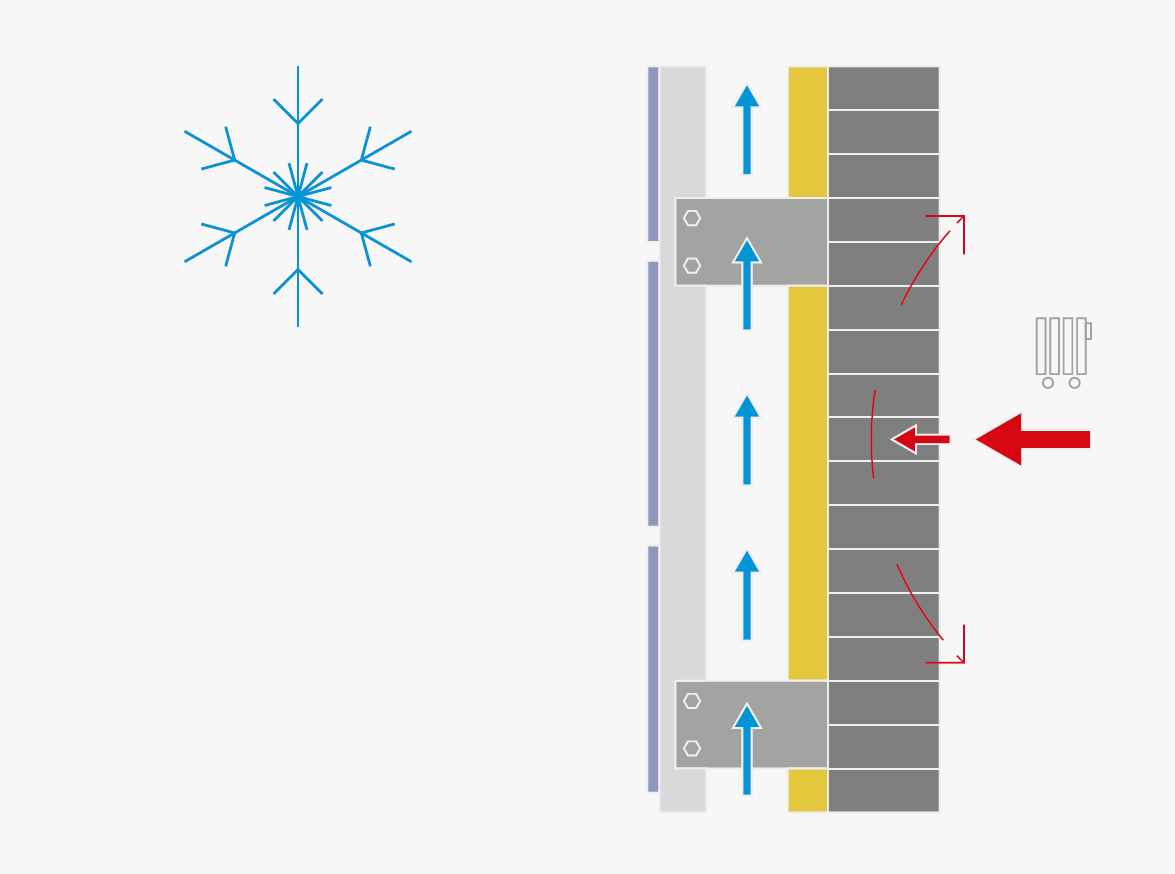

Thermal Insulation

Insulation on the external structure eliminates any thermal bridges, thus reducing temperature fluctuations inside the building for energy savings of up to 40% in some cases.

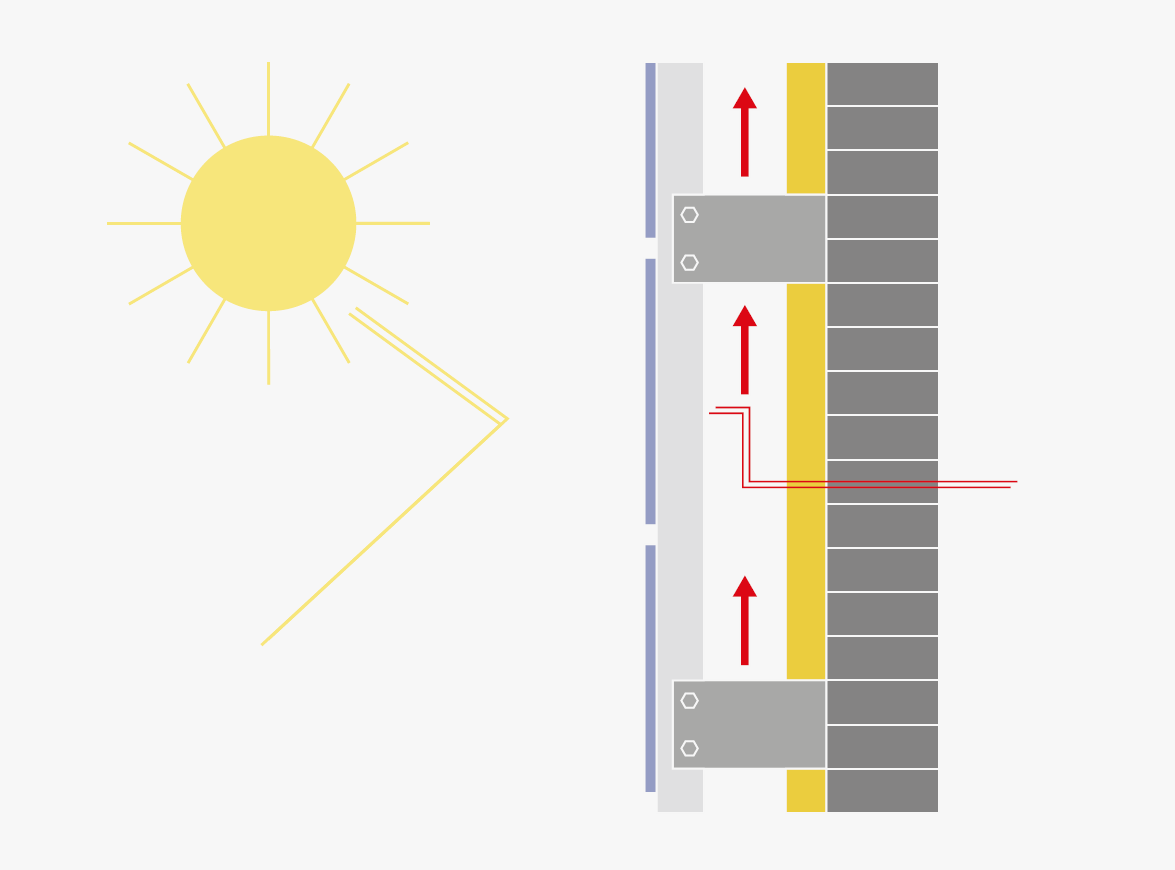

Solar Protection

The inside of the building is thermally comfortable as overheating is prevented in the summer by protecting the building from direct sunlight and other elements.

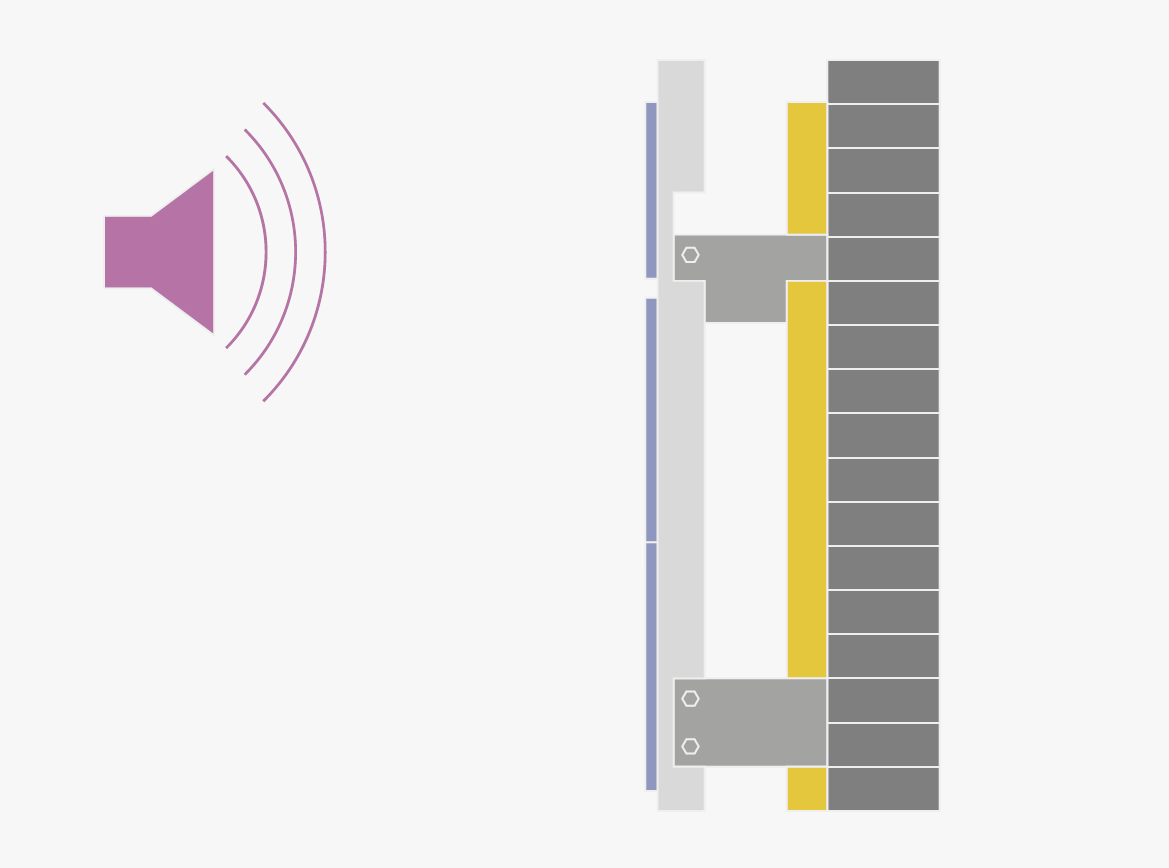

Acoustic Insulation

The noise absorption is higher since the ventilated facade system is comprised of various layers.

Water Impermeability

The chimney effect created by the air chamber provides extra protection due to the air pressure which prevents water infiltration and protects the building structure.

how it works

The Components of Ventilated Facades

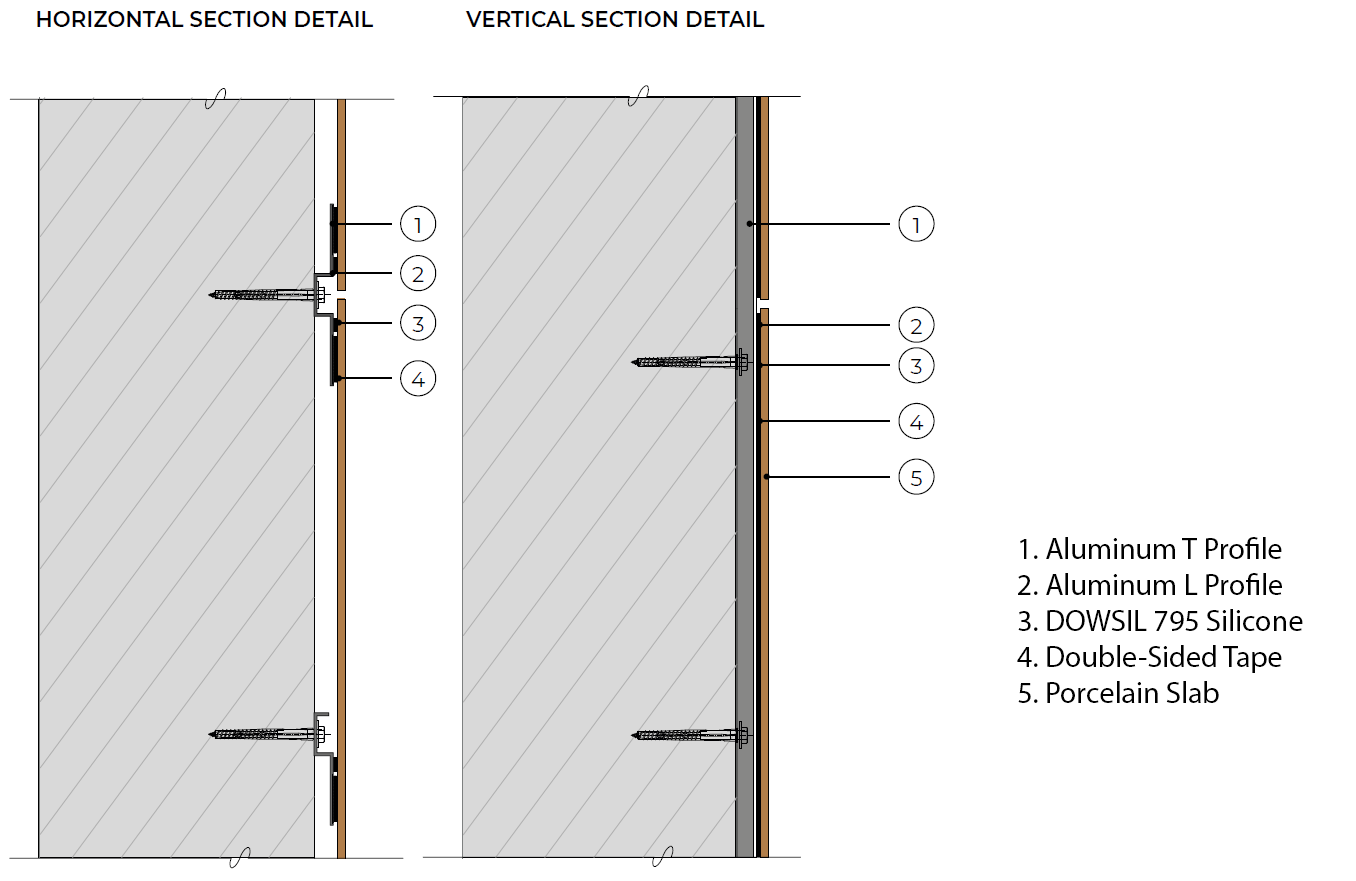

Chemically Bonded System (up to 4-storey)

Designed for exterior wall cladding with 6mm to 8mm thick porcelain slabs. For safety reasons, a fiberglass mesh is applied to the back of the porcelain slabs to prevent shattering caused by accidental breakage. It is a hidden mounting system that uses a longitudinal chemical-elastic adhesion on vertical aluminum profiles (T-100x50x2mm and L-42x50x2mm sections). The chemical adhesion consists of double-sided tape and DOWSIL 795 Silicone. The total system thickness is 22mm to 24mm with a minimum horizontal and vertical joint of 5mm between porcelain slabs.

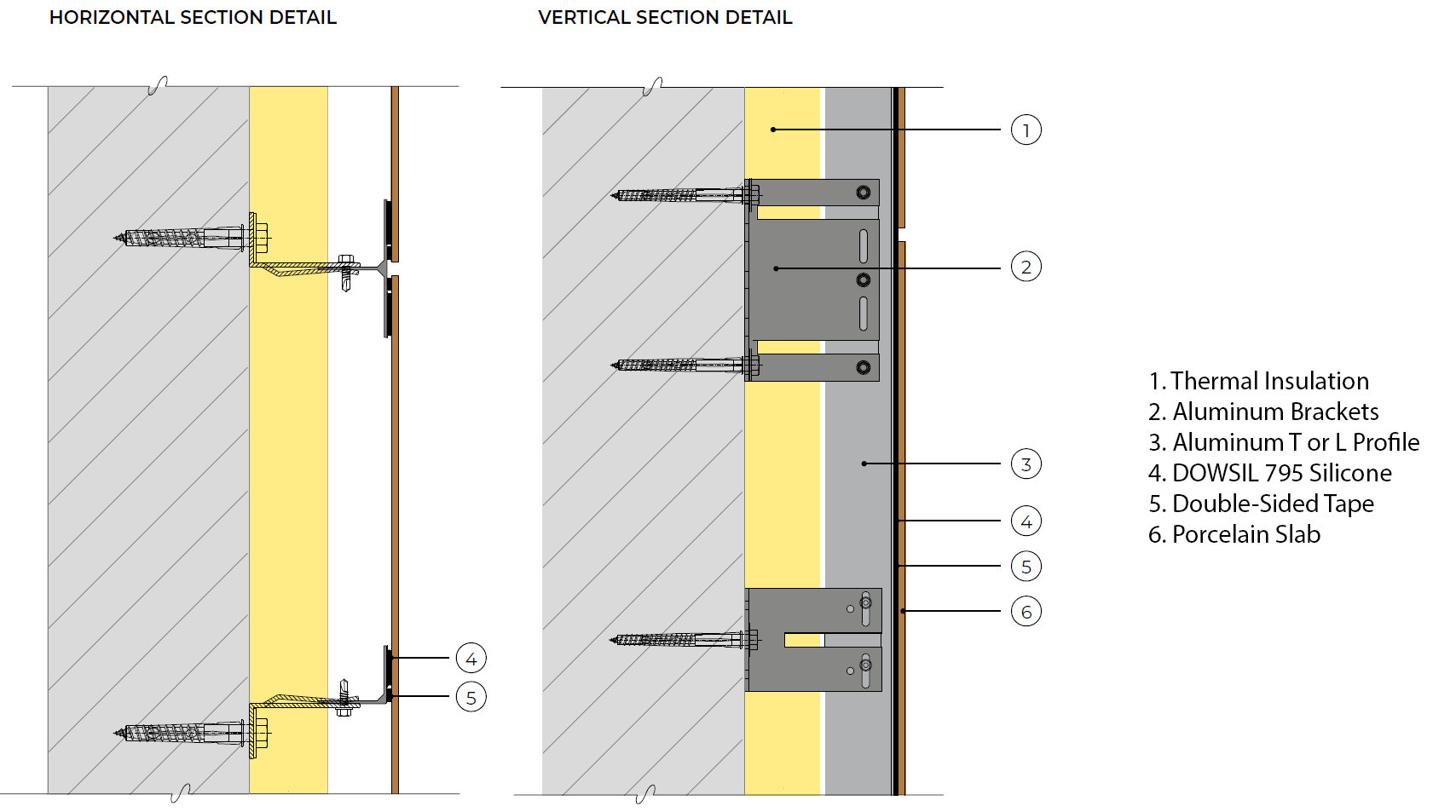

Chemically Bonded with Anchors (above 4-storey)

The exact same system as above with the added aluminum support brackets anchored into the wall and porcelain slabs. The total system thickness will vary based on the thickness of the thermal insulation used.

SLAB SELECTIONS

Porcelain Slabs for Ventilated Facades

PROJECTS

Check Out Our Ventilated Facades

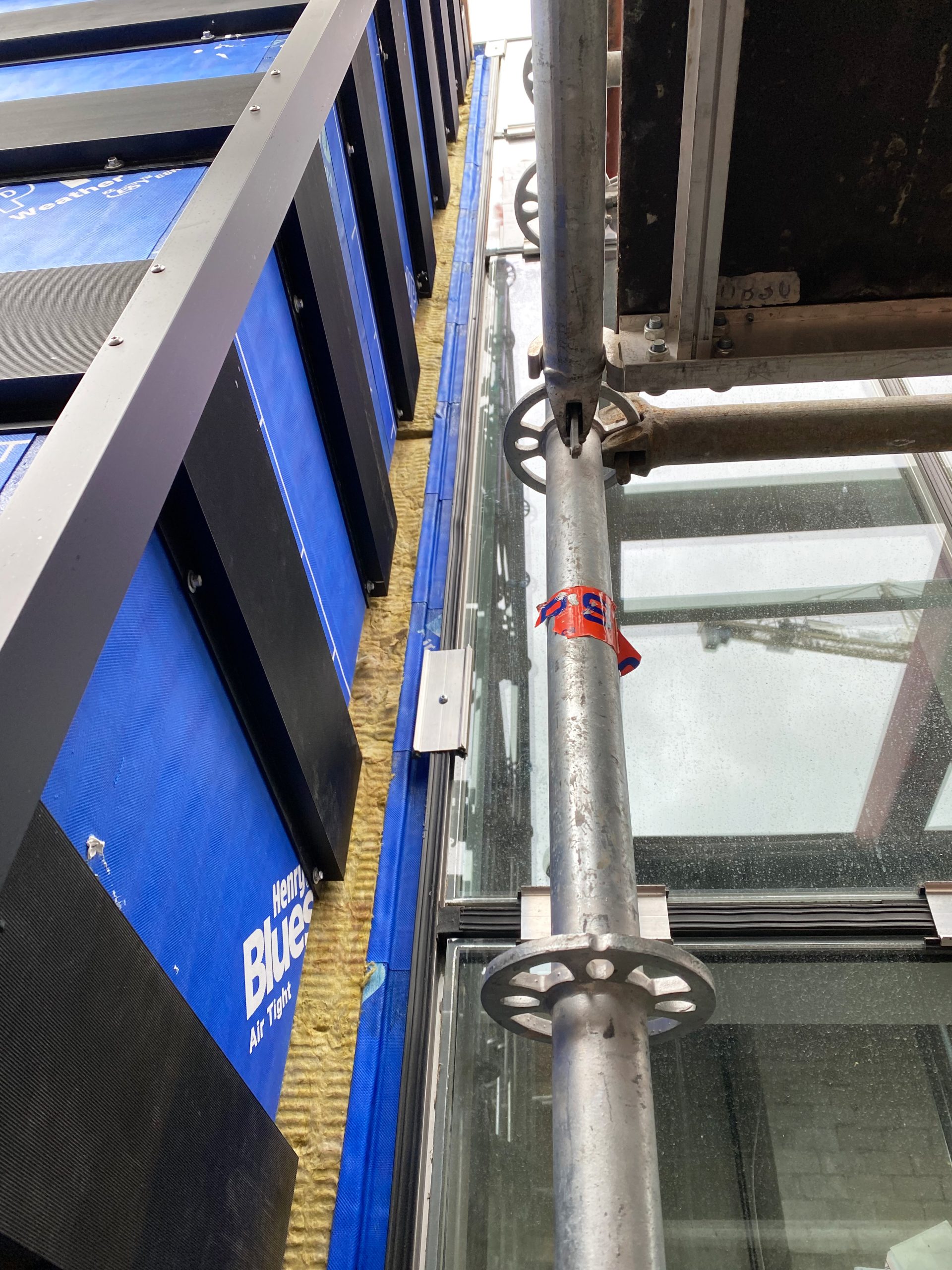

Luxury Custom Home in Ottawa

Neolith Niagara and Layla Ventilated Facade

Commercial Storefront at 256 Rideau Street in Ottawa

Neolith Calacatta Ventilated Facade

TECHNICAL INFORMATION

Adhesive DOWSIL 795 Silicone Technical Data Sheet

Dekton Declaration of Performance IMO

Dekton Declaration of Performance for Ventilated Facades

Laminam Technical Specifications for Exterior Facades

Neolith Adhesion Test Report DOWSIL 795 Silicone

Neolith CANULC-S102 Surface Burning Characteristics

Neolith CANULC-S102.2 Surface Burning Characteristics

Get a Quote

We look forward to installing quality tiles and slabs that will exceed all your expectations. Send us your project requests and general inquiries by using this form. Thank you in advance.

Coco Tile 2026 © All Rights Reserved

Website Designed & Developed By WebMarketers